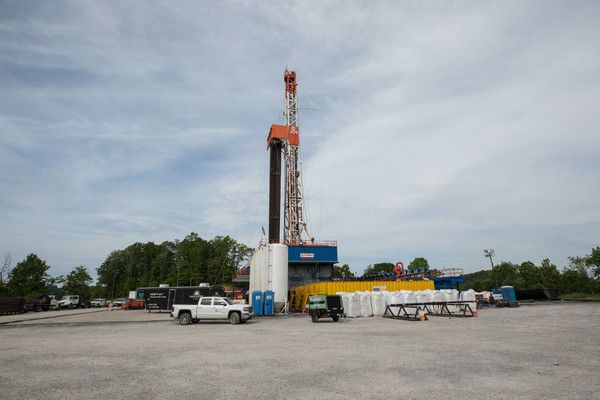

Work at MSEEL’s Boggess site near Morgantown, W.Va., is focused on learning from prior research and integrating the latest innovations to improve resource recovery and project economics while reducing environmental impacts. (Source: NETL)

Abridged information from article by John Duda and Cassie Shaner, National Energy Technology Laboratories, and published by Hart Energy. Read the full story on the Hart Energy website.

[The Marcellus Shale Energy and Environmental Laboratory mentioned in this story is a NETL funded project managed by the Energy Institute at West Virginia University.]

Hydraulic fracturing has come a long way as a means of stimulating oil and natural gas reservoirs since its first experimental use in the 1940s, thanks in large part to revolutionary technological advances led by the U.S. Department of Energy (DOE) that helped usher in the modern shale gas boom.

Established in 2014, the Marcellus Shale Energy and Environmental Laboratory (MSEEL) was among the DOE’s first field laboratories. The $25 million project was created to develop and validate new knowledge and technology to improve recovery efficiency and minimize the environmental implications of unconventional resource development.

The NETL manages the project and provides technical oversight on behalf of the Office of Fossil Energy. MSEEL, which spans two Northeast Natural Energy (NNE) production sites outside Morgantown, W.Va., is managed by the Energy Institute at West Virginia University (WVU) and involves a consortium of other universities and national laboratories.

The MSEEL’s Boggess site, established in 2018, features six horizontal production wells, including one fully instrumented with permanent fiber-optic wiring and sensors to provide near-real-time information during hydraulic fracturing and production. (Source: NETL)

Research on this project is providing new insights into the fracture stimulation and enhanced oil recovery processes, which will aid in the development of new methodologies and tools to maximize the production of oil from fractured shale. While some research results will apply to specific formations, many realistic and practical learnings will be applicable to other unconventional plays and subsurface applications, such as tight gas sand reservoirs and even saline formations for CO2 storage.

The DOE is using data collected from these demonstration projects and new field laboratory projects awarded in fiscal year 2019 to support artificial intelligence and machine learning. The results of this work will yield fundamental knowledge of shale fracture and matrix properties. Additionally, analytical tools for assessing hydraulic fracture performance and methods of targeting distinct features of the hydraulic fracture system will be developed to improve production efficiency and increase resource recovery.

T o read the full story that includes research findings, key takeaways and future steps, go to the Hart Energy website. For more information on WVU's MSEEL work, contact Sam Taylor, Energy Institute.

-EI-

1/15/2020 Published by permission from Hart Energy and NETL.

Call 1-855-WVU-NEWS for the latest West Virginia University news and information from WVUToday.

Follow @WVUToday on Twitter.